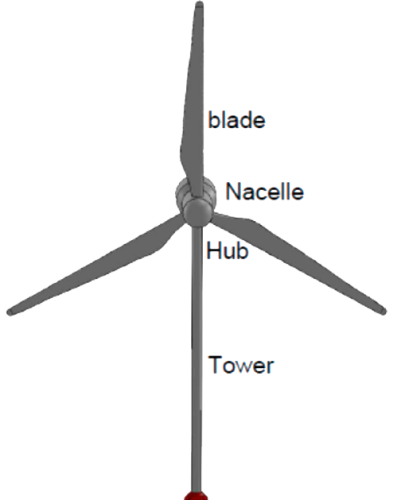

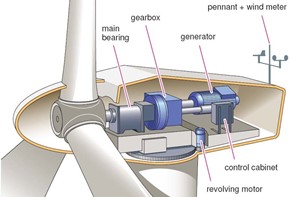

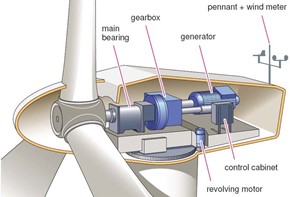

Wind turbines inevitably go through challenging lifecycles causing deterioration, eventually costing wind farm operators an extortionate amount of money to fix and in many cases, instigating them to start all over again from scratch. Decommissioning or conducting major renovations are expensive paths to go down, as is operating a turbine below peak performance causing high costs and inefficiencies. To ensure a healthy lifecycle, it’s important that wind turbines are regularly inspected and maintained for as long as they are in operation.

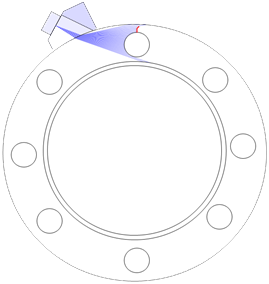

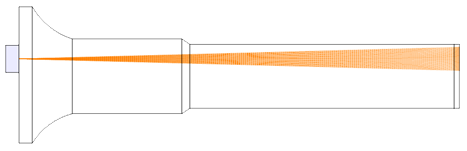

At Sonomatic RAIS, our team of highly trained technicians provide ACFM and Phased Array (PA) bolt inspections for wind turbines and their component parts during multiple stages of their lifecycle, ensuring the best performance and minimal costs for the operators.