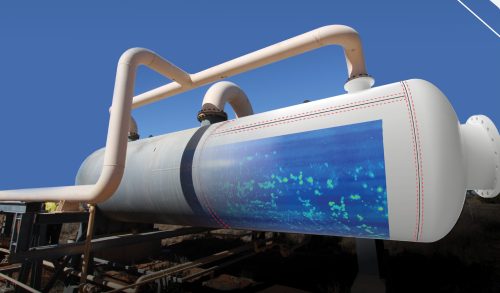

All engineered equipment has a finite life cycle and deteriorates over time with use. Sonomatic RAIS provides comprehensive in-service and offline inspection services, using our knowledgeable and experienced inspectors, across a range of industries to assist our clients with their asset integrity management and ensure industry compliance with code, statutory regulations and legislative requirements.

Interested in getting your project inspected with an in-service inspection? Get in touch with us today for more information!