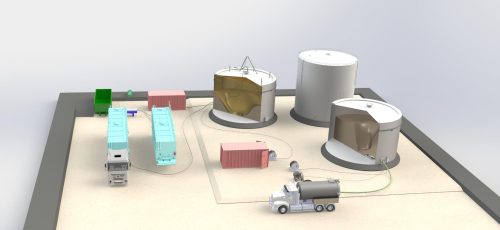

The floors of storage tanks can be susceptible to internal and/or external corrosion which may lead to failure with severe consequences. Safe management of tanks therefore relies on inspection of the floor at appropriate intervals. Historically, this inspection has been carried out by tools and techniques that rely on internal man entry following emptying and cleaning. This type of inspection relies on the tanks being taken out of service.

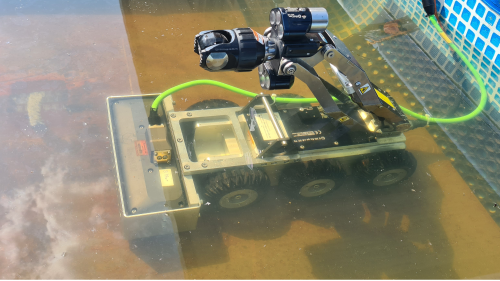

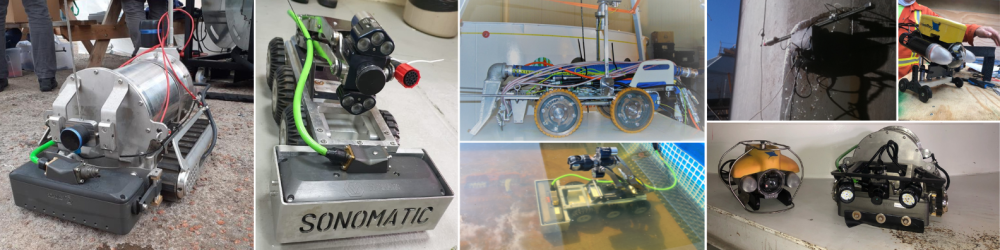

Sonomatic has developed and applies robotic technologies to deploy its world-leading automated corrosion mapping to tank floors in-service. This approach gives a high degree of assurance of tank floor integrity while avoiding the need for costly shutdowns and minimising the hazards associated with confined space entry.