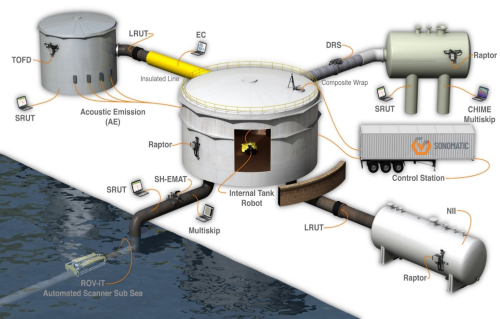

Sonomatic has over forty years of experience in the inspection industry, supplying specialist services to a wide variety of sectors. In that time, we have come to understand all of the frequently encountered challenges, how we can provide the most value to our clients, and how to perform every job we undertake safely.

RAIS provides highly trained PCN-qualified technicians to perform a number of techniques that work within regulations, codes and to our various accreditations, offering seamless NDT services and managing term contracts as well as off-shore and on-shore projects via our hand-picked technicians and admin and management teams.

Our services include but are not limited to: