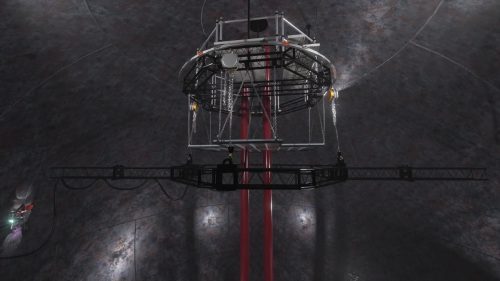

SPHERA (Sonomatic’s Portable, High-Resolution, Efficient, Remote-Controlled, Autonomous crawler.) is a Sonomatic RAIS developed, semi-autonomous weld inspection tool for the internal and external inspection of spheres and other carbon steel vessels.

SPHERA is the result of our creative and innovations team at Sonomatic RAIS. Our engineers, technicians and industry experts worked together to create a concept that paves the way for a safer, more effective and economical approach to inspecting inside confined spaces. Changing the way the data is collected, significantly increasing the quality and quantity of the data and ultimately reducing confined space entry, costs and the impact on our environment.