The next generation MEC™ technique is a fast and reliable method for the detection of corrosion and defects in pipes, pressure vessels, and drums. Applied during the process conditions, the MEC™ technique ideally supports the Non-Intrusive Inspection (NII) strategy.

MEC™ Pipescanner

Capabilities

MEC (Magnetic Eddy Current) is the next generation and a further development of the industry proven fast corrosion screening SLOFEC™ technique.

Pipe & Pressure Vesse; Capabilities using MEC™:

- High defect detection sensitivity in pipes with OD 1” to 56”, WT up to 30mm, coating up to 15mm and pressure vessels with WT up to 30mm, coating up to 5mm.

- Ability to detect internal and external corrosion and defects including isolated pits of very small diameter and volume.

- No coating removal and minimal surface preparation prior to inspection.

- Ability to inspect horizontal and vertical pipes and pressure vessels of different steel materials (carbon and stainless steel, duplex, super duplex) and coating types (GRP, rubber, paint).

- Direct sizing of defects during scanning without the need for Ultrasonic verification.

- Defect assessment, integrity and monitoring support.

Benefits

- High sensitivity and reliability in detecting topside and underside / internal and external defects including small and shallow pitting caused by bacterial corrosion (from Ø >3mm and 10% wall loss).

- Direct sizing of defects during scanning without the need for Ultrasonic verification with accuracy of +/- 10% for onsite reporting and +/- 5% for special offline analysis.

- No coating removal for a faster and more economical inspection operation.

- Ability to inspect through higher wall and coating thickness.

- Analysis of defect severity in terms of volume and wall loss.

- Differentiation of defects from non-defects such as inclusions and laminations.

- Enables fast and efficient scanning and C-scan mapping of large areas.

- Low cleaning requirement prior to inspection.

- Ability to inspect under various temperatures.

Equipment

The comprehensive reporting software provides accurate, reliable and repeatable real time inspection results. The advanced colour condition mapping report provides an analysis of

detected defects in terms of size, wall loss severity and location. Separate reports are also generated for the internal and external conditions.

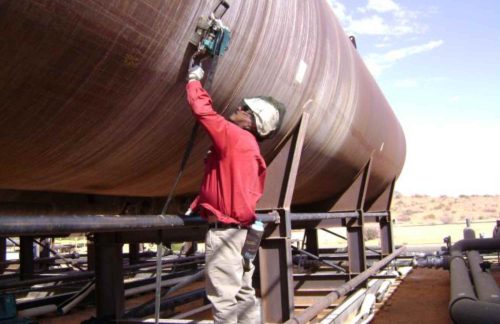

The MEC™-Pipescanners are designed and built for the high-speed and high-performance inspection of pipes and pressure vessels.

Features:

- Improved signal to noise ratio for enhanced defect detection level.

- Rapid magnet on/off operation for faster positioning and manoeuvring from track to track during scanning.

- Ability to change the scanning lift-off for inspecting surfaces that are not well-cleaned.

- Compatible poleshoes and wheelsets.