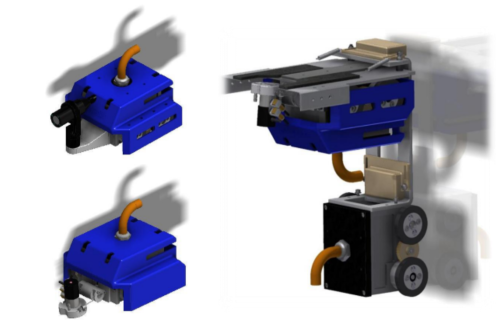

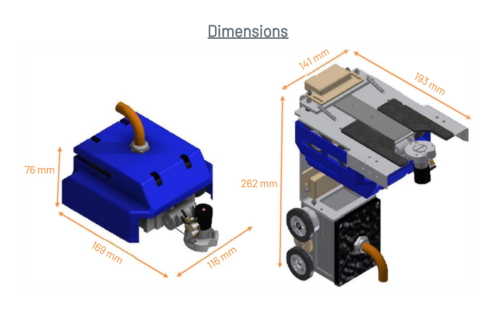

Sonomatic has developed an End Dome Robotic Inspection System (EDRIS). This miniature scanner revolutionises the inspection process by eliminating the need for manned entry. With its advanced deployment system, the scanner can be easily attached to the skirt, allowing for seamless deployment to the domed end. Currently, the scanner is equipped with a video-tracked corrosion mapping inspection technique, but we are continuously developing and engineering alternative attachments and inspection tooling in collaboration with our clients.

Developed to support NII of vertical pressure vessels, one of the most critical areas to inspect in vertical pressure vessels is the bottom head, particularly the domed end. This area is highly susceptible to corrosion due to fluid movements caused by differential pressure. Traditionally, inspecting these locations can be challenging, as the skirt is welded to the tangent line of the head, creating an inaccessible area or requiring confined space entry. However, Sonomatic has successfully addressed this issue with the development of the EDRIS Scanner, ensuring efficient inspection that meets the Non-Intrusive Inspection (NII) requirements for vertical pressure vessels.