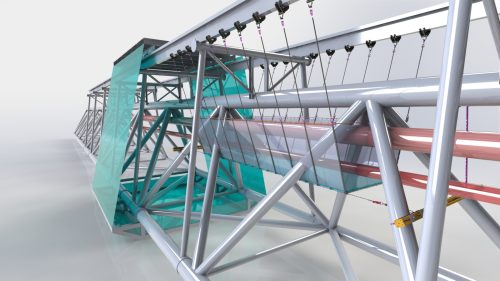

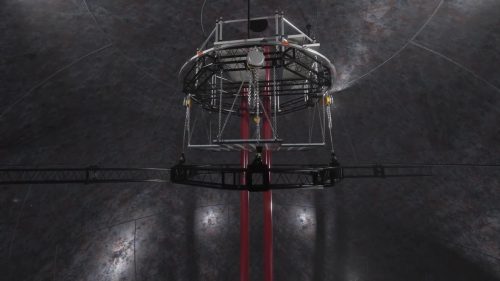

Sonomatic RAIS offers a wide variety of services that include inspection, work at height consultations, suspended working platforms, tensioned netting systems, confined space work, confined space rescue cover and many more. These services can be carried out across all sectors, including but not exhaustive to offshore/onshore oil and gas, petrochemical industries, renewable energy industries, civil engineering, the built and natural environment.