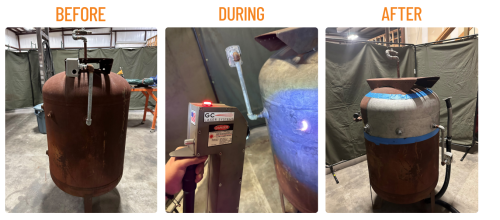

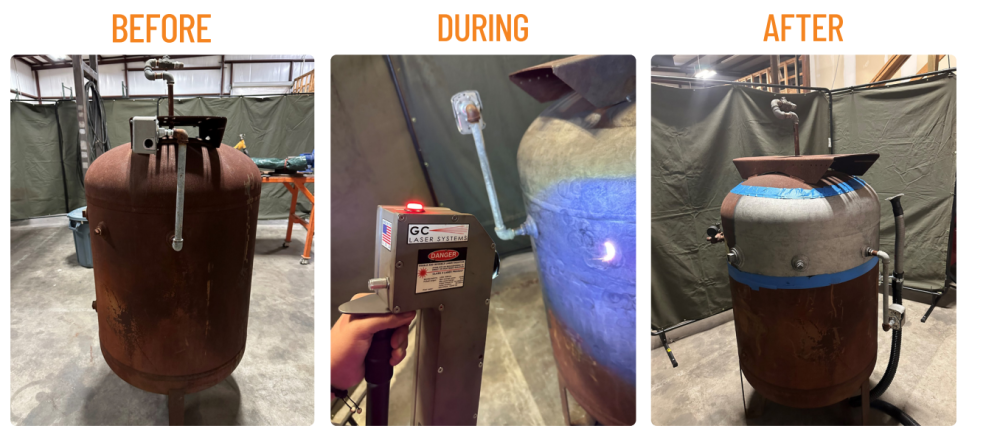

As a company constantly striving for the newest technology to improve our industries, Sonomatic RAIS have invested in a multitude of laser cleaning systems. When submicron pollution particles adhere to a workpiece surface, they often stick very tightly, making it impossible to remove them with conventional cleaning methods.

However, cleaning the workpiece surface with lasers is very effective. Laser cleaning is a non-contact method of cleaning, making it very safe to clean precision workpieces or their fine parts and ensure their accuracy. Therefore, laser cleaning has unique advantages in the cleaning industry.

Find out more about our various laser cleaning solutions by contacting us today!